Vehicle Traffic Control System

Our client owns an automotive assembly plant. Its production facilities include multiple parking sections used for various purposes.

The client uses just-in-time production model, which means that the stock of used materials and items is minimal, enough for 4–6 hours. There are several parking lots around the factory and there are a few tens of trucks delivering supplies from vendors every day.

Parking and unloading were managed manually—the dispatchers made decisions about truck unloading on their own. To define, which truck should be unloaded first, the dispatcher needed to know not only how many materials or details of the same kind are in stock, but also how long the stock will last. If these decisions were not optimal, some parts in the warehouse might run out before the stock was replenished. In this case, the assembly conveyor was forced to stop.

The client needed to develop a brand-new system for automated management of the vehicle queue that prioritizes the unloading of those parts and materials that need to be restocked first. In addition, the system was supposed to simplify the work of dispatchers and reduce waiting times for drivers. The system should be scalable and integrated with existing enterprise information systems.

Since our team had to create the system from scratch, we had to manage the development of both parts, namely the web application for dispatchers and Android app for drivers.

Web Application

The web application downloads from the server the GPS location of each truck as well as the data on the stock of the transported goods from the enterprise information system (SAP). Based on this information, the system prioritizes the deliveries and forms a queue for unloading.

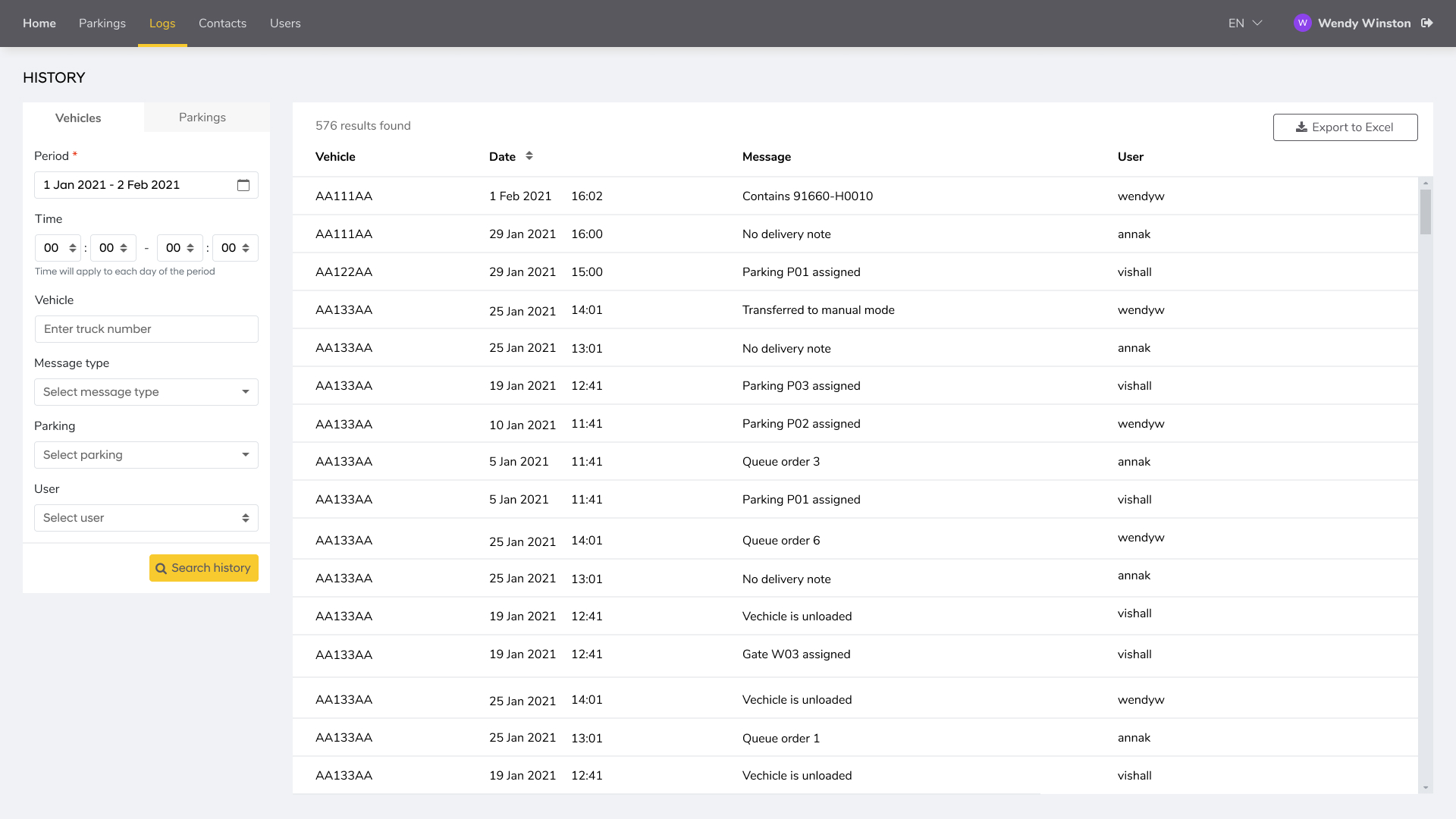

Besides, the web application displays the location of each vehicle in the parking lot, in the queue and in the waiting area, and also saves data and provides the possibility to view the history of events and changes.

Figure 1: History screen

Figure 1: History screen

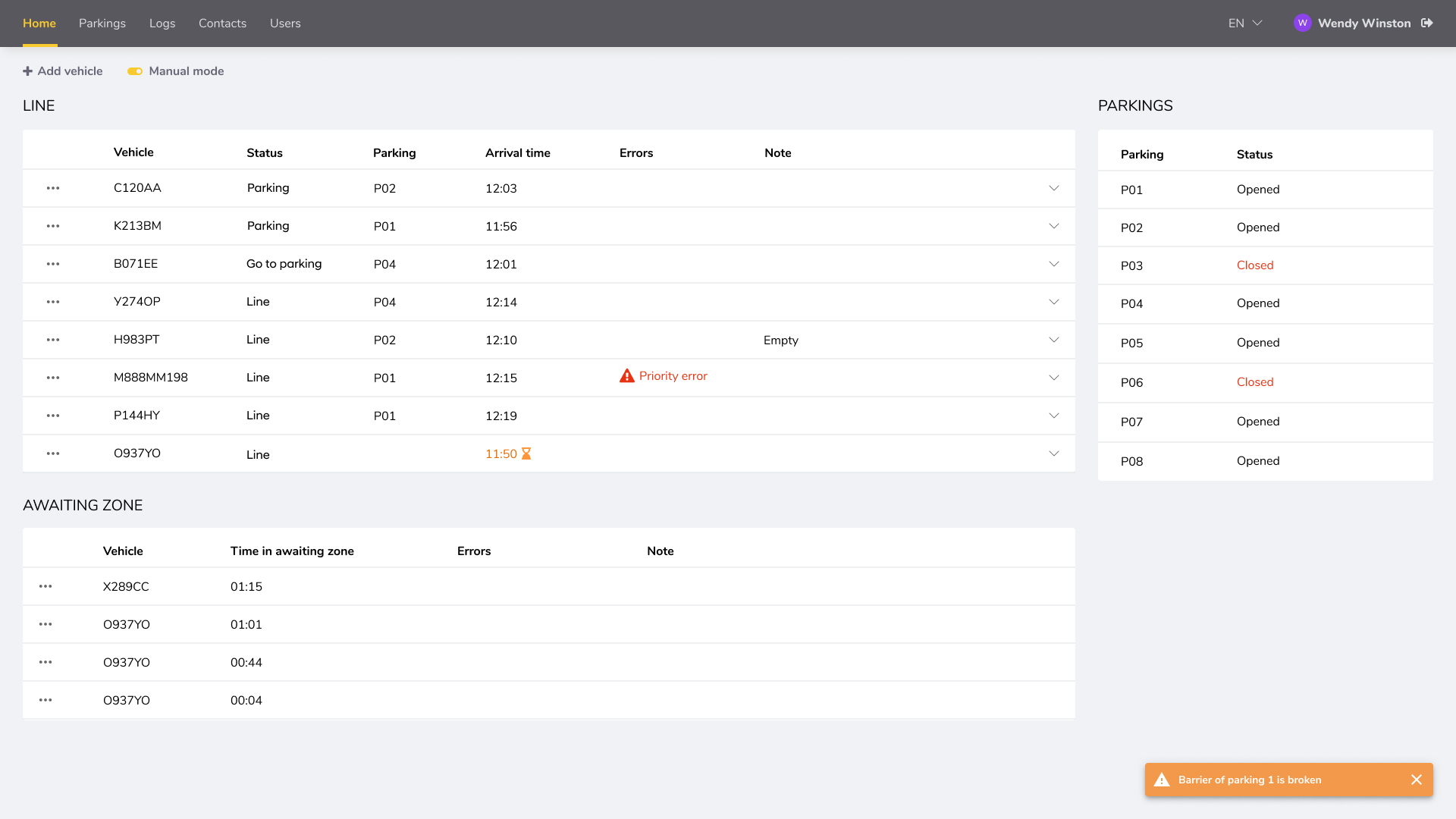

In automated mode, the system calculates the position of each vehicle in the queue based on delivery priority, arrival time and critical events. If it is required to correct the electronic queue, the dispatcher can do it manually.

In the event of an emergency, the dispatcher receives an alert and promptly resolves the problem. He can

- change the position of the vehicle in the queue,

- send it to another parking location in accordance with the information received from internal sources,

- manage the status of checkpoints.

Figure 2: Application home screen

Figure 2: Application home screen

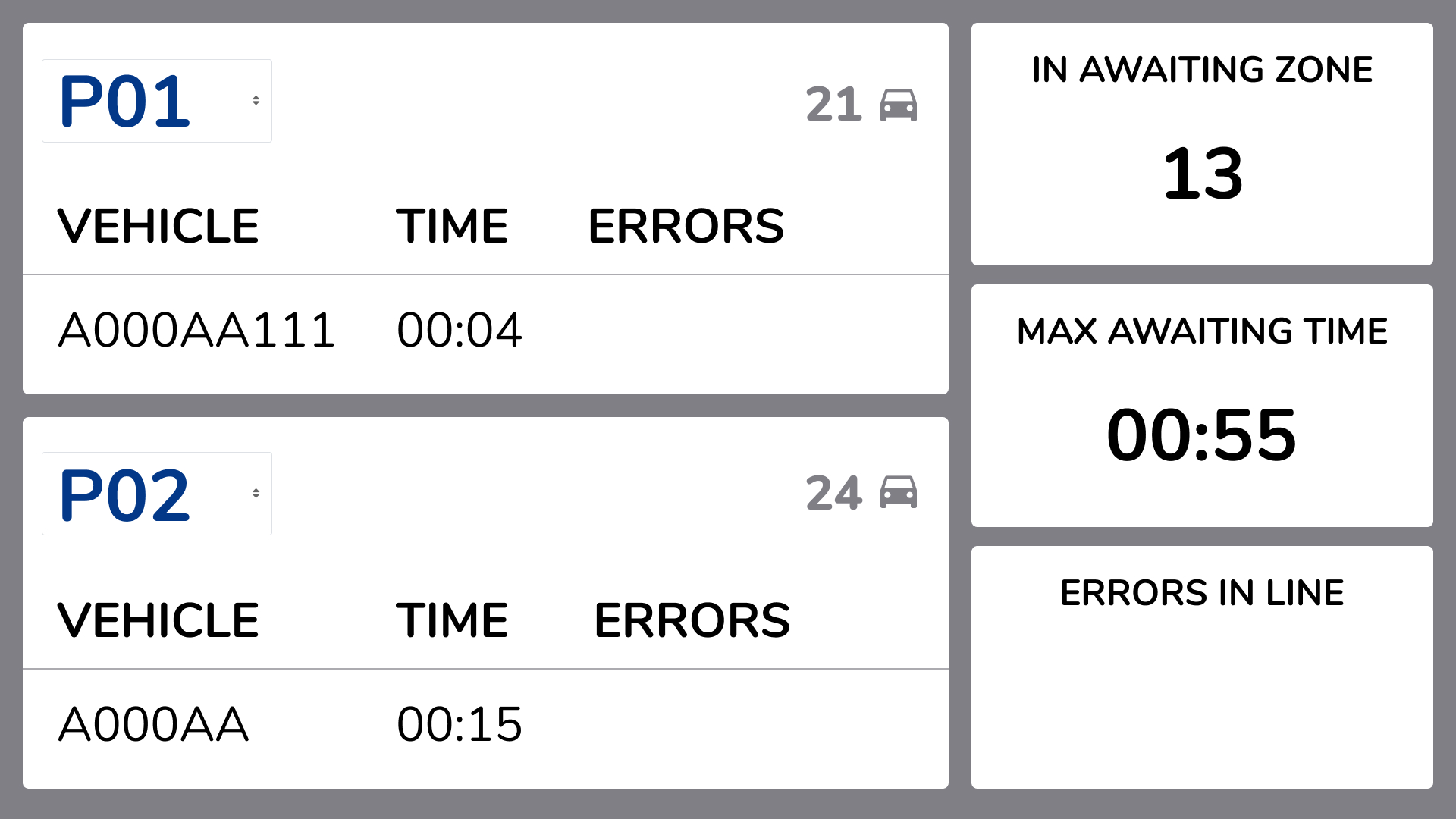

The web application also has an additional feature—showing vehicle queue on a TV screen:

Figure 3: TV Screen

Figure 3: TV Screen

Mobile Application

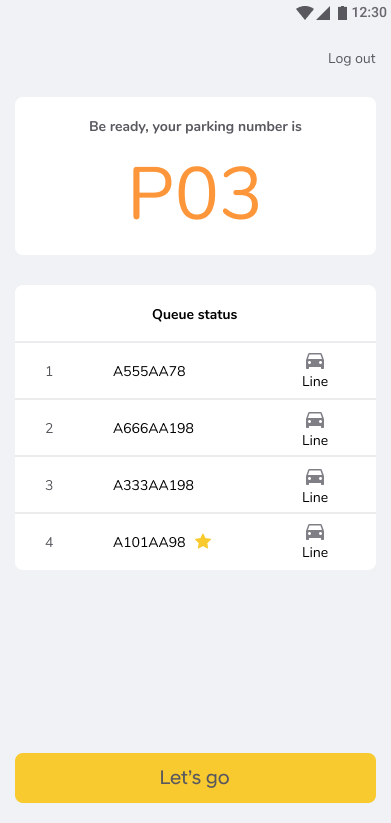

The drivers get special smartphones with the Android application installed. The application blocks any attempts to run any other apps on the smartphone. It sends GPS coordinates to the server, which are then used by the web application to calculate real vehicle location and determine where the vehicle is at the current moment.

The app also provides the drivers with the information on the queue and prompts what to do next.

Figure 4: Mobile app screen

Figure 4: Mobile app screen

Technologies Used

We designed the web application using .NET Core and Vue.js. As a result, we implemented a modern lightweight application with a simple yet powerful user interface.

The mobile application was created using Kotlin.

Software Country's team was fully responsible for UX design, graphic design, system architecture, implementation, testing, and deployment of both the web and mobile applications. We also enabled integration with the client’s ERP system.

All the client’s requirements were fulfilled:

- cost-effective solution is deployed on mid-range servers and cheap smartphones

- the system is fully integrated into the client's environment.

We built web and mobile applications, created UX, and extended the features that cover the needs of the client. The system allows our client to manage vehicles in a more efficient and convenient way.

Related Cases

Read allRTSM Solution: Data Ingestion Improvement

Removing issues in data architecture and processing in order to provide a solid foundation for future growth of the platform.

LMS Content Import and Export Feature

A solution for importing and exporting content from / to Moodle and IMSCC platforms.

Content Generation with Copilot Studio and MCP Servers

A solution to help new teachers rapidly adapt to the educational system while providing easy access to the existing content base.